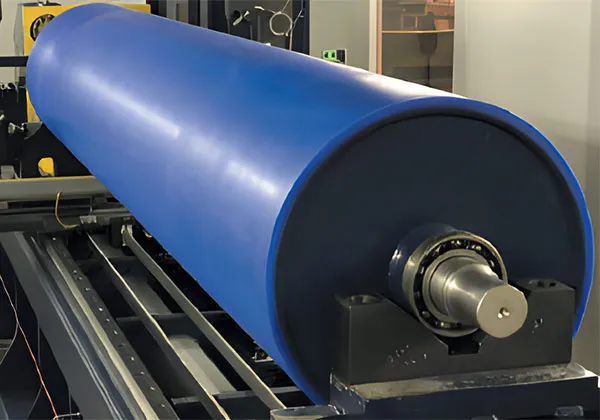

Rubber Roller

Manufacturer in China

Get factory price start from cocoroller

Cocoroller offers superior Custom Rubber Rollers, crafted for unmatched performance and lasting durability to elevate your operational success.

Tailored Precision

Experience bespoke accuracy with our custom-fitted rubber rollers, designed to seamlessly integrate with your specific machinery requirements.

Durability Guaranteed

Our rubber rollers stand the test of time, providing robust performance and prolonged lifespan, reducing the need for frequent replacements.

Innovative Solutions

Leverage cutting-edge technology and materials with our innovative rubber rollers, setting new standards for efficiency in your industry.

Revolutionary Products

Diverse Materials, Versatile Applications: Harness the potential of our vast material selection for your custom rubber rollers, catering to a multitude of industrial applications. From heat-resistant silicone to robust polyurethane, our materials are tailored to meet the demands of your specific operational environment, ensuring optimal performance across various sectors.

Neoprene

Printing

Mirror

PU

Industry

EPDM

Nylon

NBR

Hypoly

Silicone

What Sets Us Apart

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation. Take the example of booking a tall container of products:

Strong Capacity

Powerhouse Production: Our robust manufacturing capabilities enable us to handle large-scale orders with ease, ensuring timely delivery without compromising on quality.

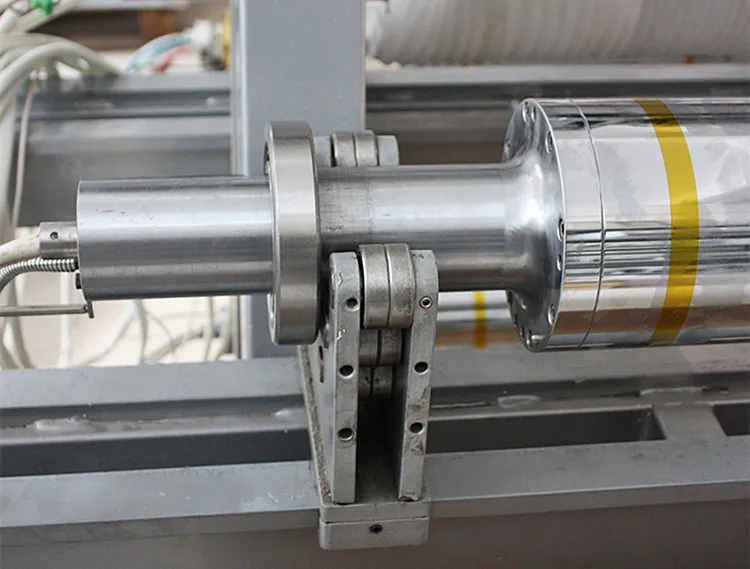

Well-Equipped

Technological Edge: Our state-of-the-art facilities are equipped with advanced machinery, allowing for the production of superior rubber rollers that meet diverse industrial needs.

Favorable Pricing

Cost-Effective Quality: We offer competitively priced rubber roller solutions without sacrificing quality or performance, providing you with excellent value for your investment.

Full Support & Service

Comprehensive Care: From initial consultation to after-sales support, we provide full-service assistance, ensuring a hassle-free experience and satisfaction at every turn.

We're There Every Step of The Way

Step 1: Consultation & Customization

Tailored to Your Needs: From the very first interaction, we listen closely to understand your requirements, ensuring that our solutions are customized to match your specific needs.

Step 2: Precision Manufacturing

Crafted with Precision: Our manufacturing process employs state-of-the-art technology and meticulous attention to detail, ensuring that every product is of the highest quality and precision.

Step 3: Quality Assurance

Guaranteed Excellence: Each stage of production is accompanied by stringent quality checks to guarantee that our rubber rollers not only meet but exceed industry standards.

Step 4: Efficient & Reliable Shipping

Seamless Delivery: We understand the importance of timely delivery, which is why we’ve streamlined our shipping process for efficiency and reliability. Rest assured, your custom rubber rollers will arrive on schedule, ready for immediate use.

Want to know Price list?

Applications

Each application leverages the unique properties of rubber rollers, such as their elasticity, resistance to chemicals, and ability to withstand high temperatures, making them indispensable in modern manufacturing and processing industries.

Rubber rollers are essential in transferring ink evenly in printing machines, ensuring high-quality print output.

In textile mills, rubber rollers are used for fabric processing, including feeding, stretching, and finishing fabrics.

They play a crucial role in conveyor systems, providing the grip and movement necessary to transport goods.

Rubber rollers are utilized in packaging machinery to facilitate the handling and packing of different products.

These rollers are critical in the paper-making process, aiding in the pressing, drying, and finishing of paper.

Rubber rollers are used for coating, painting, and finishing in steel processing plants.

They assist in the lamination process, ensuring smooth and even application.

Fill The Form Below

Frequently asked Questions

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

It's essential to consider the roller's intended use, the environment it will operate in, and the material it will be in contact with. Factors such as temperature resistance, chemical compatibility, hardness, and durability are critical. Our experts can help guide you through the selection process to ensure you get the best roller for your needs.

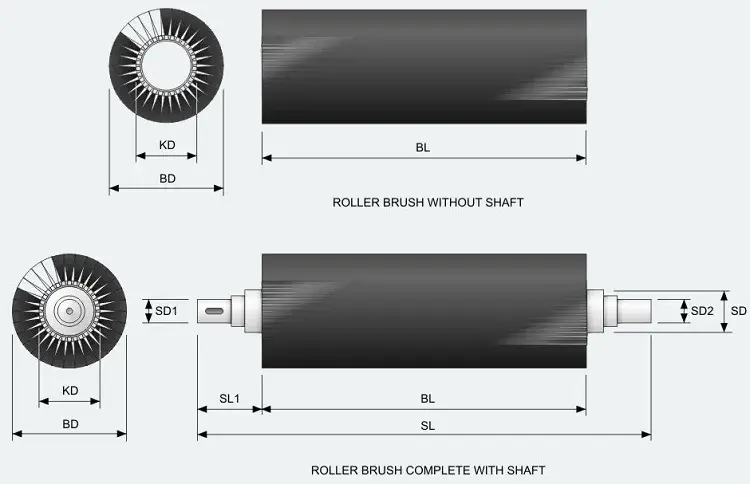

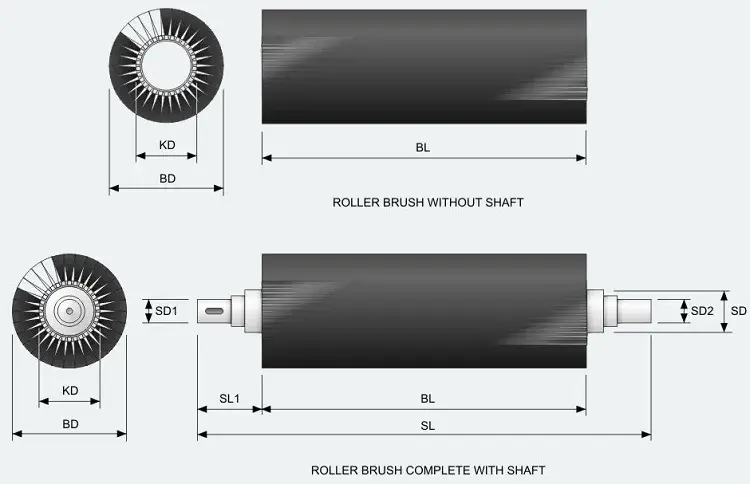

Absolutely. We specialize in customizing rollers to your exact specifications. Just provide us with the dimensions, material preferences, and performance requirements, and we'll manufacture rollers that fit your unique machinery perfectly.

Quality is our top priority. We follow a strict quality control process that includes material inspection, in-process control during manufacturing, and final product testing. We ensure that every roller meets both our high standards and international quality standards before it leaves our factory.

Lead times can vary based on the complexity and quantity of your order. Typically, custom orders are completed within 4-6 weeks. However, we strive to accommodate urgent requests and can discuss expedited options.

We stand behind our products with comprehensive after-sales support. This includes installation guidance, maintenance tips, and troubleshooting. If you encounter any issues with our rollers, our customer service team is ready to assist you promptly to resolve any concerns.