![]()

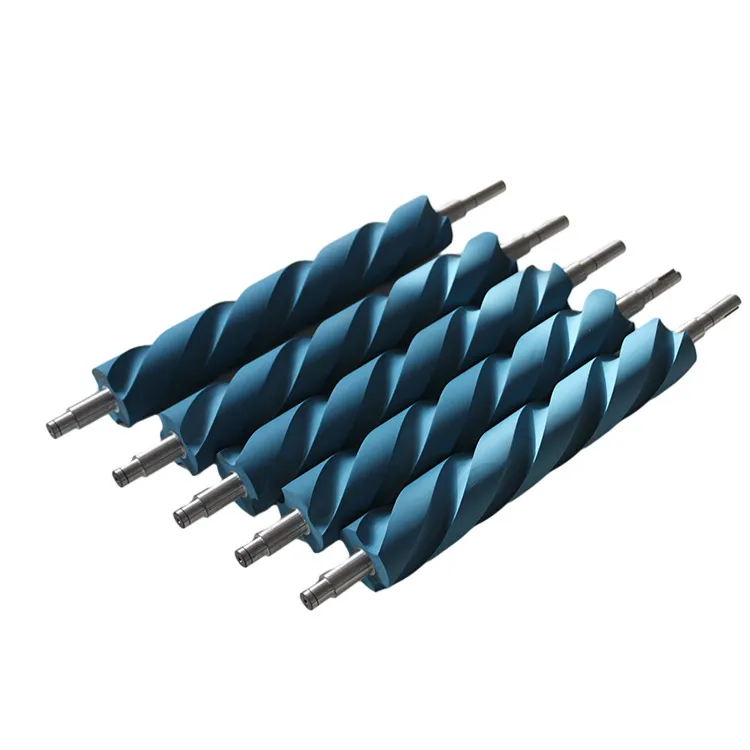

When it comes to plastic film production, every detail counts. One often overlooked yet critical component is the rubber roller—a small hero that determines the smoothness and quality of your finished product.

Rubber rollers play a crucial role in enhancing plastic film quality by ensuring precise tension control, reducing defects, and maintaining uniformity. Their surface finish directly influences film smoothness, minimizing wrinkles, tears, or uneven textures. Proper roller selection and maintenance lead to improved efficiency, lower production downtime, and consistently high-quality results.

The relationship between a rubber roller's surface and film smoothness might seem straightforward, but there’s more to it. Let’s break it down step by step.

Understanding the Relationship Between Roll Surface and Film Smoothness

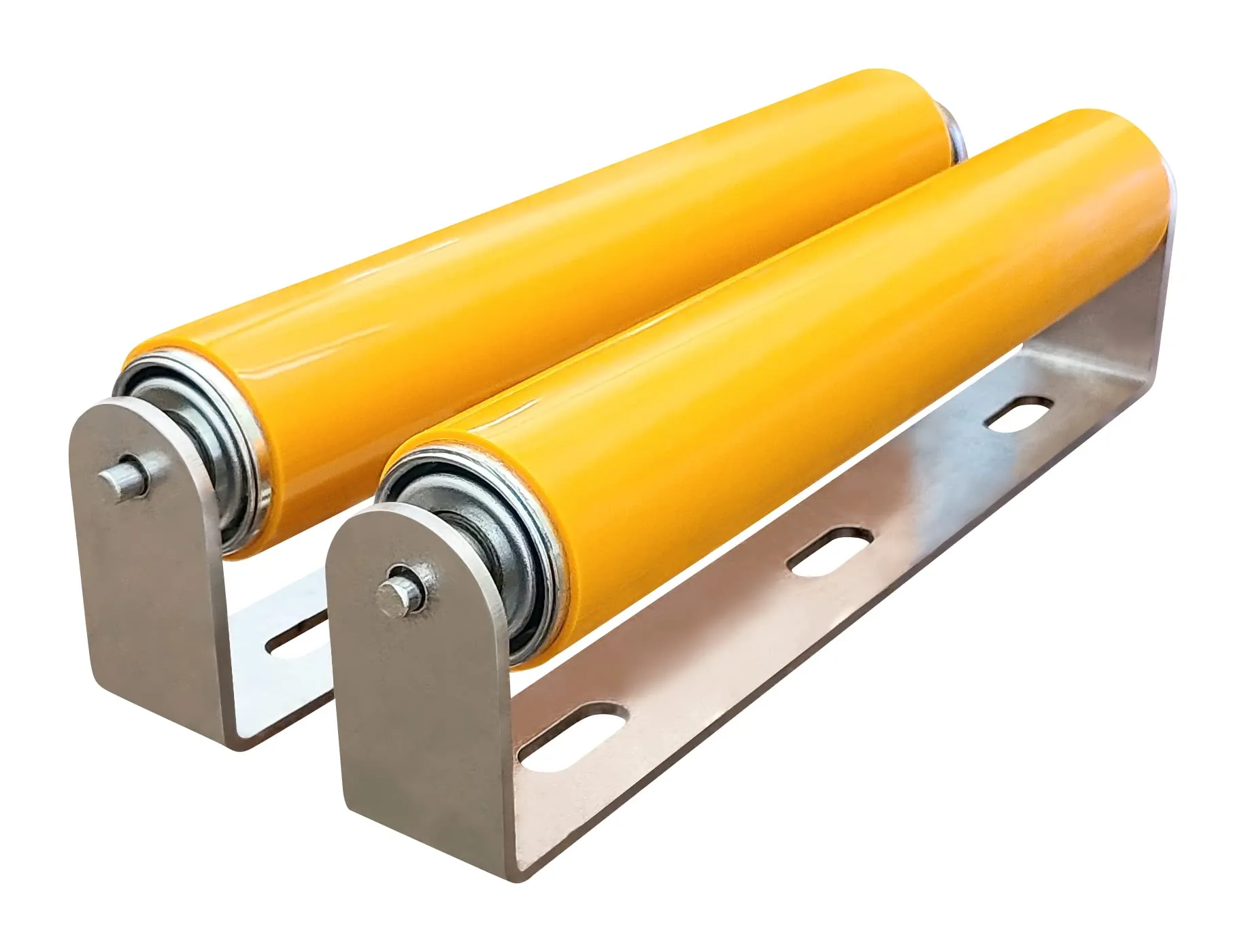

The roll surface plays a pivotal role in how plastic film behaves during production. A well-prepared roller surface guarantees smooth contact, which prevents defects.

A smoother roller surface ensures even pressure distribution across the plastic film. This reduces surface marks, wrinkling, or tension imbalances during production. The right roll material, combined with a consistent surface texture, helps produce flawless film with superior clarity and strength.

![]()

Dive Deeper: How Roller Surface Influences Film Smoothness

If you’ve ever experienced wrinkled or uneven plastic film, chances are the roller surface was the culprit. Here’s how:

1. Surface Texture

Rubber rollers with a polished, uniform texture create smooth film contact. When surface irregularities—like tiny scratches or abrasions—exist, they distort the pressure applied to the film, leading to defects like waves, streaks, or tiny air pockets.

Example: Imagine pressing dough with a rolling pin. A dented pin leaves uneven thickness; the same happens with damaged rollers.

2. Material and Coating Selection

Not all rubber rollers are created equal. Rollers come in varying hardness (measured in Shore A) to meet different production needs. For plastic films, softer rollers are ideal because they conform better to slight inconsistencies.

| Roller Type | Film Type | Key Benefit |

|---|---|---|

| Soft Rubber Rollers | Thin, flexible films | Smooth, wrinkle-free output |

| Hard Rubber Rollers | Thick, rigid films | Precise pressure control |

3. Consistent Roll Maintenance

Even the highest-quality rubber rollers degrade over time. Frequent cleaning and resurfacing prevent the buildup of debris, which can scratch the plastic film surface or create uneven pressure.

Tip: Regularly inspect rollers for wear and tear. Small fixes now can save big costs down the road.

4. Tension Control

Rubber rollers also play a role in controlling tension. Improper tension can pull plastic films unevenly, leading to stretching or tearing. A smooth roller surface ensures consistent tension throughout the production line.

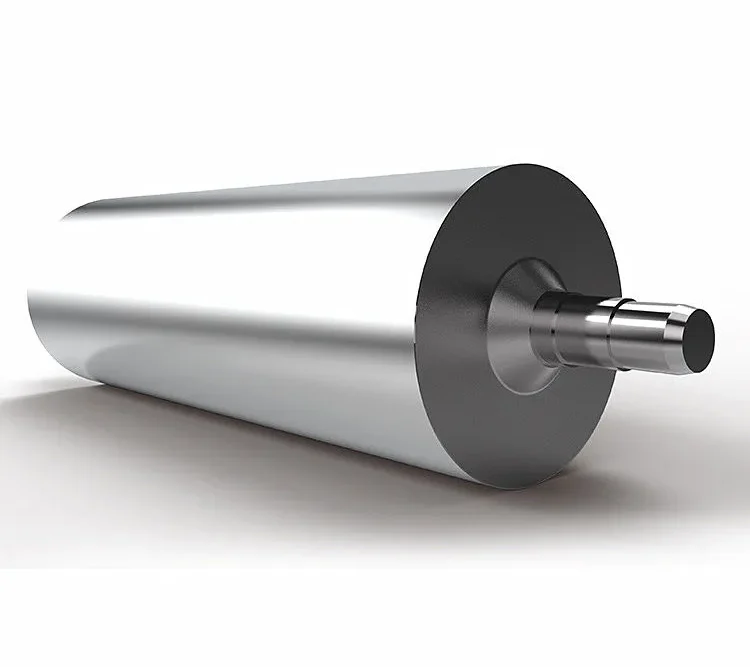

How Does Roller Hardness Impact Film Durability?

Different rubber roller hardness levels impact the plastic film’s strength and durability in significant ways.

Rubber hardness directly affects how the roller distributes pressure on the film. Soft rollers provide flexibility, reducing stress on the film and preventing stretch marks. Hard rollers offer precision for applications requiring high strength and uniform thickness.

Let’s take a closer look:

- Soft Rollers: Perfect for fragile films. They absorb minor inconsistencies and prevent tearing.

- Hard Rollers: Best for thicker films where precise pressure and durability are key.

In my experience, clients often make the mistake of using one type of roller for every film type. Investing in the correct hardness tailored to your product makes a noticeable difference—both in output quality and production efficiency.

How Can Poor Rollers Disrupt Film Efficiency?

Here’s the truth: poor-quality rollers can be a silent profit-killer.

Worn-out rollers or rollers with inconsistent surfaces can cause production issues like film wrinkling, uneven coatings, or tearing. This results in increased material waste, more downtime for troubleshooting, and higher repair costs.

I once had a client who ignored their rollers for too long. They ended up dealing with significant film wrinkles, wasted raw materials, and delays in delivery. After upgrading their rollers and maintaining them properly, the difference was night and day—production ran smoother, waste dropped, and the team saved time.

Why Invest in High-Quality Rubber Rollers?

Here are some key benefits:

- Reduced Downtime: Fewer disruptions due to roller issues.

- Lower Defect Rates: Improved surface consistency leads to fewer production flaws.

- Enhanced Output Quality: Smooth rollers ensure wrinkle-free, durable film.

- Long-Term Cost Savings: Investing in quality rollers reduces replacement and repair costs.

Conclusion

The surface quality of your rubber rollers directly impacts the smoothness and efficiency of plastic film production. By choosing the right material, maintaining consistency, and ensuring proper tension control, you can significantly improve both output quality and productivity.

Invest in your rollers—your production line will thank you.