Basic Process Flow for Rubber Products Manufacturing:

With the rapid development of modern industries, especially the chemical industry, there is a wide variety of rubber products. However, their production processes are fundamentally similar. The production process of rubber products using solid rubber (raw rubber) as the main material mainly includes the following steps:

- Raw Material Preparation

- Compounding

- Mixing

- Molding

- Vulcanization

- Trimming/Finishing

- Quality Inspection

1. Raw Material Preparation

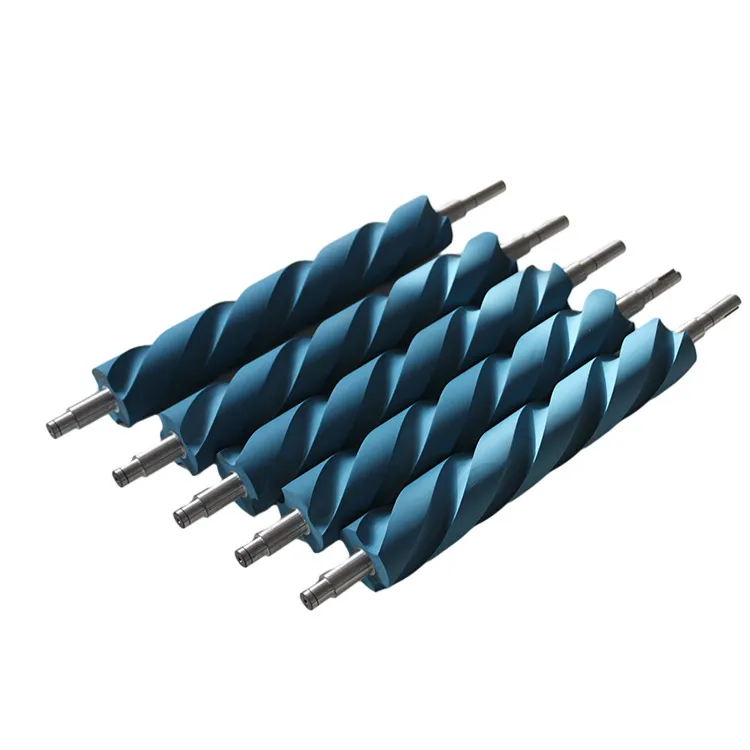

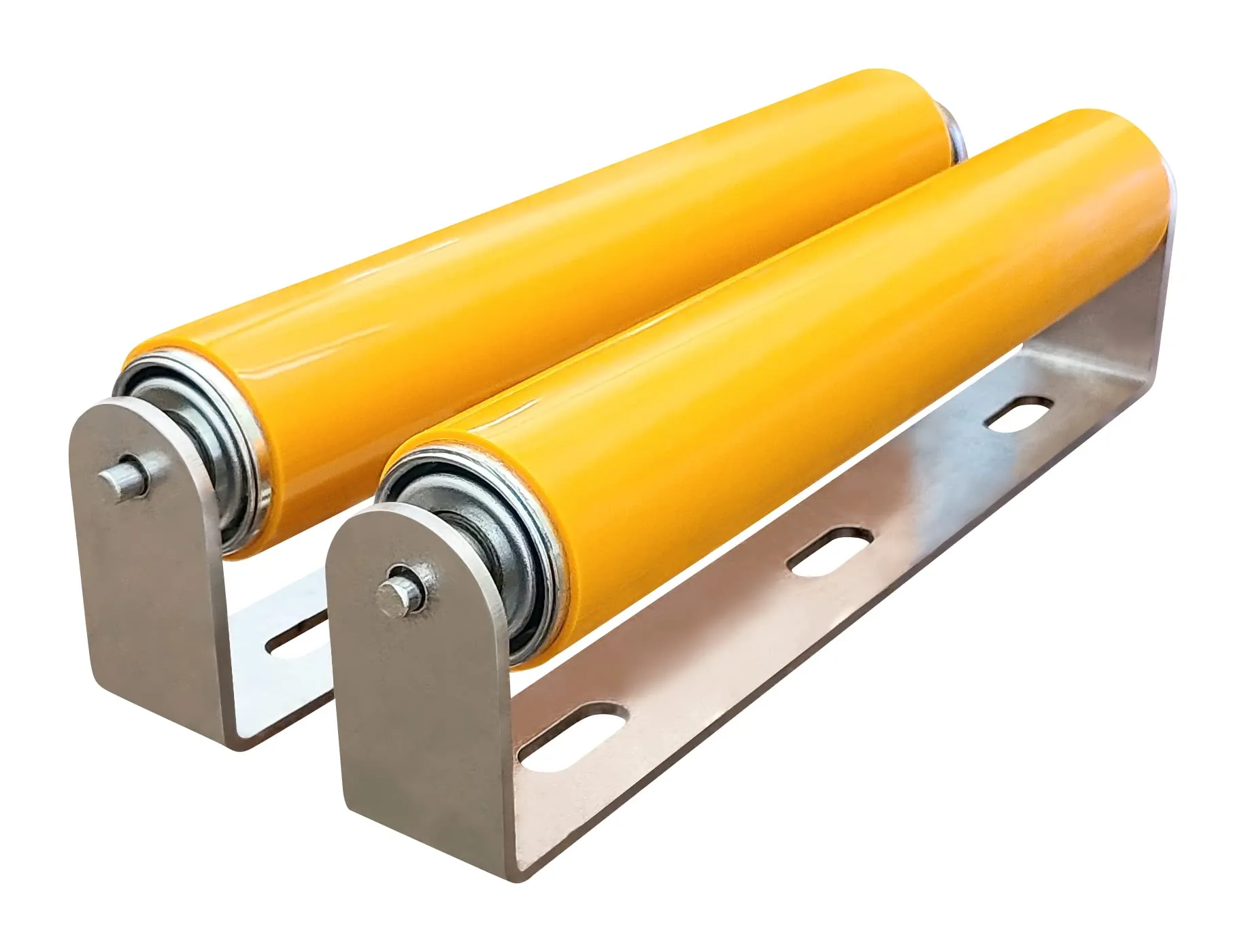

Rubber products mainly consist of raw rubber, compounding agents, fiber materials, and metal materials. Among these, raw rubber is the primary material, while compounding agents are added to improve specific properties of rubber products. Fiber materials (such as cotton, flax, wool, various synthetic fibers) and metal materials (such as steel wires, copper wires) serve as the skeleton materials of rubber products to enhance mechanical strength and limit product deformation.

During the raw material preparation process, ingredients must be accurately measured according to the formulation. To ensure proper mixing of raw rubber and compounding agents:

- Raw rubber needs to be softened in an oven at 60-70°C before being cut and broken into small pieces.

- Block-shaped compounding agents like paraffin, stearic acid, and rosin need to be pulverized.

- If powdered compounding agents contain mechanical impurities or coarse particles, they need to be sifted to remove them.

- Liquid compounding agents (such as pine tar, guamalon) need to be heated, melted, water evaporated, and impurities filtered out.

- Compounding agents need to be dried; otherwise, they may clump together, fail to disperse evenly during mixing, and cause bubbles during vulcanization, thus affecting product quality.

3. Mixing

Raw rubber is elastic but lacks the necessary processing properties (plasticity), making it unsuitable for processing. To improve its plasticity, raw rubber undergoes mixing. This process breaks down the long-chain molecules of raw rubber, making it more plastic and facilitating the even dispersion of compounding agents. There are two methods of mixing raw rubber: mechanical mixing and thermal mixing.

- Mechanical Mixing: This method involves degrading the long-chain rubber molecules into shorter ones through mechanical squeezing and frictional forces at relatively low temperatures.

- Thermal Mixing: In this method, hot compressed air is introduced into the raw rubber, causing the long-chain molecules to degrade into shorter ones under the influence of heat and oxygen.

4. Compounding

To meet various usage conditions and obtain different properties while reducing costs, different compounding agents are added to raw rubber. Compounding involves mixing the plasticized raw rubber with compounding agents in a mixing mill to ensure complete and uniform dispersion. This step is crucial, as uneven mixing can compromise the effectiveness of rubber and compounding agents, affecting product performance. The resulting material from compounding is called compound rubber or rubber compound, which is used as a semi-finished material for various rubber products.

The rest of the process, including molding, vulcanization, trimming, and quality inspection, follows similar principles across rubber product manufacturing. Would you like to dive into specific details about any of these steps or have any other questions?